Our Product

Our Product

DECAION

ULTIMATE SOLUTIONS FOR COOLING WATER TREATMENT

DeCaIonTM (DCI)

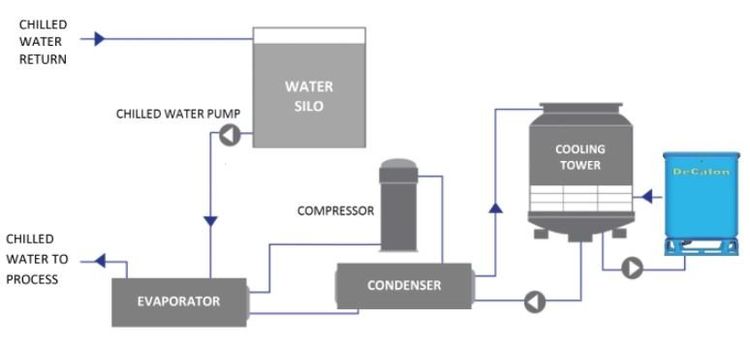

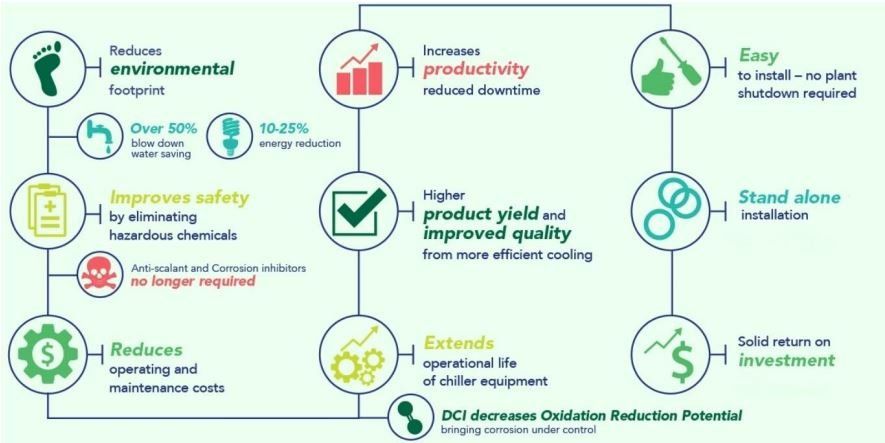

is a revolutionary approach to eliminating scale, preventing corrosion and bio-fouling automatically in cooling water systems. Through applied electro-chemistry and an intelligent controller, DCI removes water hardness from cooling systems without the need for hazardous chemicals. The innovation provides a green technology solution to scaling and corrosion in large building HVAC systems and industrial chiller circuits. The DCI system removes existing scale deposits and prevents further scale formation by driving a non spontaneous redox reaction which precipitates CaCO3 and Mg(OH)2 at the cathode. The main causes of scaling, Ca2+ and Mg2+, can then be dumped off the recirculating cooling water. SiO2 is also removed. The system operates continuously so design heat transfer efficiency is maintained at all times and the requirement for routine shut downs and chemical descaling is no longer required. Water blow-down quantities are also substantially educed.

Conventional method uses eco unfriendly 100% chemical approach. But scale deposits still build up on heat exchanger tubes, pipes and cooling towers which will then require hazardous chemical cleaning and waste disposal. The blow-down containing chemicals from cooling tower pollutes the waterways. On the other hand, pseudo scientific Non Chemical Devices yield unsatisfactory results. This compromised situation cannot be solved by continuing the same practice. This is why eco friendly DeCaIonTM (DCI)

System enhanced by

CataGreenTM (CG)

is now introduced to circumvent the problems of the above approaches.

BIO mutation which is a common phenomenon

when chemicals are used to kill the microbes is

now history.

The Ultimate Solution to Scaling, Corrosion and Fouling Problem

DecaIon removes scales by electrolysis according to:

- Ca2+ + HCO3- + OH- = CaCO3 + H2O

- Mg2+ + 2OH- = Mg(OH)2

The main scaling culprits in water system i.e. Mg2+ and Ca2+ are dissolved from the pipes, heat exchanger and cooling tower, deposited on cathodes, dislodged and blown down automatically. Disinfectant is also produced. Anti-scalant, biocides and corrosion inhibitor are no longer needed. CataGreenTM and DCI act in concert to provide a CHEMICAL FREE APPROACH!

In addition, hard, glass-like SiO2 scale can now be removed and prevented.

What Does DCI Do?

- DCI dissolves and removes existing hardness and silica scales and prevents future occurrence continuously.

- DCI+CG enhances the overall performance by preventing bio-fouling effectively.

- DCI removes Dissolved Oxygen and reduces ORP.

- DCI creates an alkaline environment to control corrosion and also to increase Silica solubility.

Industrial Chiller

Scale Removal in industrial condensers and cooling towers reduces energy, water, maintenance and chemical costs.

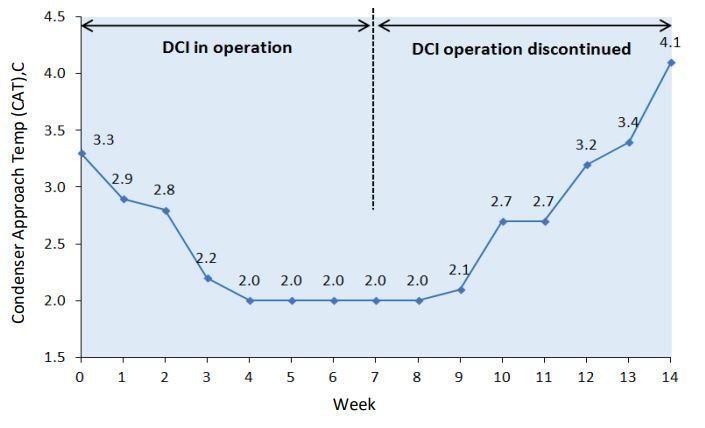

WATER COOLED HVAC SYSTEM

A significant improvement in heat transfer and lower condenser approach temperatures leading to increased

chiller efficiency.

Easy to use Automation

- The intelligent controller auto regenerates and maintains electrode performance

- Auto Scale Dislodge and Discharge

- Auto Conductivity Control

- Auto Amperage Control

- Communication Capabilities

SITE PERFORMANCE

SIMTech-A*STAR Singapore

An independent party, SIMTech-A*STAR Singapore (Website: www.a-star.edu.sg) was engaged to evaluate the performance of DCI (Case Study Code: I15-E-125W). The followings were prepared and presented by them.

Power Saving - 17.5%

A Semi-conductor Factory in Philippines

Power Savings - 11.2%

Water Savings - 27%

Chemical Savings - 70% (without CataGreen)

A Syrup Factory in Malaysia

Power Savings - 16.9%

Water Savings - 88%

Chemical Savings - 100%

BENEFITS OF DECAION

GENERAL SPECIFICATIONS

Dimension (~mm)-overall: L = 700, B = 380, H = 1300

Weight: ~55 Kg

Max Power Consumption:

~600 W

Max Operating Amp (DC):

15 A auto adjustable

Max Flow: 2.25 m3/h

Operating Pressure:1 bar

Input Power Source:Single Phase AC 110-240V, 50/60Hz

KIJ Ultra Supreme Filtration Sdn. Bhd.

Plot 226, Lengkok Perindustrian Bukit Minyak 3,Kawasan Perindustrian Bukit Minyak,14100 Simpang Ampat,Pulau Pinang, Malaysia.

Contact

Tel: +604-501 6013 (Hunting)

Fax: +604-502 4622sales@ultrasupreme.com.my

© 2024

All Rights Reserved | KIJ Ultra Supreme Filtration Sdn Bhd

Designed by Trinity42